Approved fire proof paint applicator of

Dubai Civil Defense

Surface preparation and cleaning to remove all rust, Mill scale, debris, existing paint from the surface as well as to create a surface profile for adhesiveness of subsequent coating

(Paint Application of Special

Architectural Finish)

A special coating for Steel Structure that can give special aesthetic and smooth finish by applying epoxy fillers and industrial paints

(Intumescent & Cementitous)

Intumescent is a fire proof coating for steel that can give a highly decorative finish. It works by expanding in a fire, creating a dense char and keeps the failure temperature of the steel below its critical failure level for periods of up to 3 hours.

Welcome to Asmeco

ASMECO is a privately owned company established in 2012 . We are one of the leading service provider for Anti corrosion, Abrasive blasting, Protective coating and fire proof painting (Intumescent and Cementitious) in UAE. The company operates with the fundamental principle of attaining customer loyalty through quality and service. To enable the management to achieve this modest goal, a well-equipped facility of 120,000 Sqft area comprising of latest equipments, testing instruments and material handling system.

The professional management set-up comprises of experienced managers, qualified engineers , NACE certified QC engineers and trained technicians, who adopt most modern coating techniques together with a prudent approach throughout the processes of fire proof & protective coating.

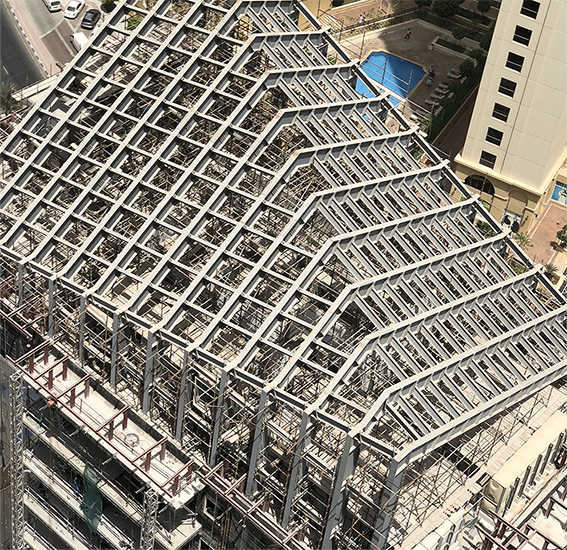

Structural Coating

Surface preparation is the essential first stage treatment of a steel substrate before the application of any coating, and is generally accepted as being the most important factor affecting the total success of a corrosion protection system.

Intumescent Coating

A coating for steel that can give a highly decorative finish. It works by expanding in a fire, creating a dense char and keeps the failure temperature of the steel below its critical failure level for periods of up to 3 hours

Aess Coating

Architecturally exposed structural steel (AESS) can express the structural integrity of a building in a striking way and put the structural system at the aesthetic forefront. Today, many buildings showcase AESS to provide an identity and even reate iconic structures.

Marine Coating

Marine paints and coatings are applied to fixed and floating marine structures such as offshore oil rigs, and recreationalboats and yachts. Included are passenger ships, reighters,tankers, container ships, fishing boats and ferries, as well as oil rigs, inland waterway ships,barges and tow boats.

Pipe Coating

Steel pipelines are used all over the world for cross country transport of natural gas, crude oil, water, petrochemical and petroleum products at high pressures over long distances. These pipelines are protected against corrosion by external and internal coating systems

Vessels Coating

Pressure vessels are probably the most complicated area to protect. Besides the pressure itself, there are challenges in the chemical processes in the vessel and the temperatures that often accompany them,and it is important to be clear on the exact needs.

Oil Tank Coating

Years of service and chemical corrosion can harm the inside of tank preventing it from properly protecting its contents. Tank lining and coating is a key factor in preventing not only product contamination but also corrosion.

Cementitious Coating

Cementitious fire protection is normally spray applied using specialist equipment to protect structural steel or concrete from the effects of fire for a nominal fire resistance period.

Scope Of Services

Working With Us

We implement different projects, innovative technologies and use an individual approach for every client!

Why Asmeco

A comprehensive coating solution under one roof for Abrasive Blasting, Fire proofing & Protective coating, AESS painting, Testing & Inspection.

Approved fire proof paint applicator of Dubai Civil Defense.

Trained and certified Employees

Own transportation service to collect and delivered the goods anywhere in UAE.

15 -20 year experienced sprayers familiar with all the Industrial, Marine and Fire Proof Coating products.

120,000 Sqft facility and 24 hours operation including dispatch and receipt of material..

Approved applicator of JOTUN, SIGMA, HEMPEL, PHOEINX, PPG, KANSAI, BERGER AKZONOBEL.

Mobile crews for onsite jobs

10 -15 year experienced blasters to work in confined space, crude oil tanks, Offshore & Marine jobs, Rigs & Ships, Structures & Pipes Lines.

Project Gallery

Our Featured Projects

Our Service

What We Do

Get a Quote

Get a Quote Form

Contact Us

Contact with us

Blasting & Painting Standard

ISO 8502-4

a) Ambient & steel temperature, b) Relative humidity, c) Dew point

ASTM D 4940 a) Grading & cleanliness, b) Size, c) Oil, moisture,

rust scale, etc. d) Chloride content

ISO 8501 100% visual of all surfaces

Residual dust on Blast cleaned surface ISO 8502-3

Salt content on blasted surface ISO/TR 15235 (Elcometer SCM 400)

ISO 8502-6, 9 (Bresle method)

Roughness / Surface profile ISO 8503-5 (Replica tape)

ISO 8503-1 (Comparator)

Holiday detection NACE RP 0188

Dry film thickness ISO 19840 / SSPC-PA2

Pull-off test ISO 4624 & ASTM D 4541 sample/block.

Curing test (for IOZ primer) ASTM D 4752 (MEK test)

Project Gallery